제품상세

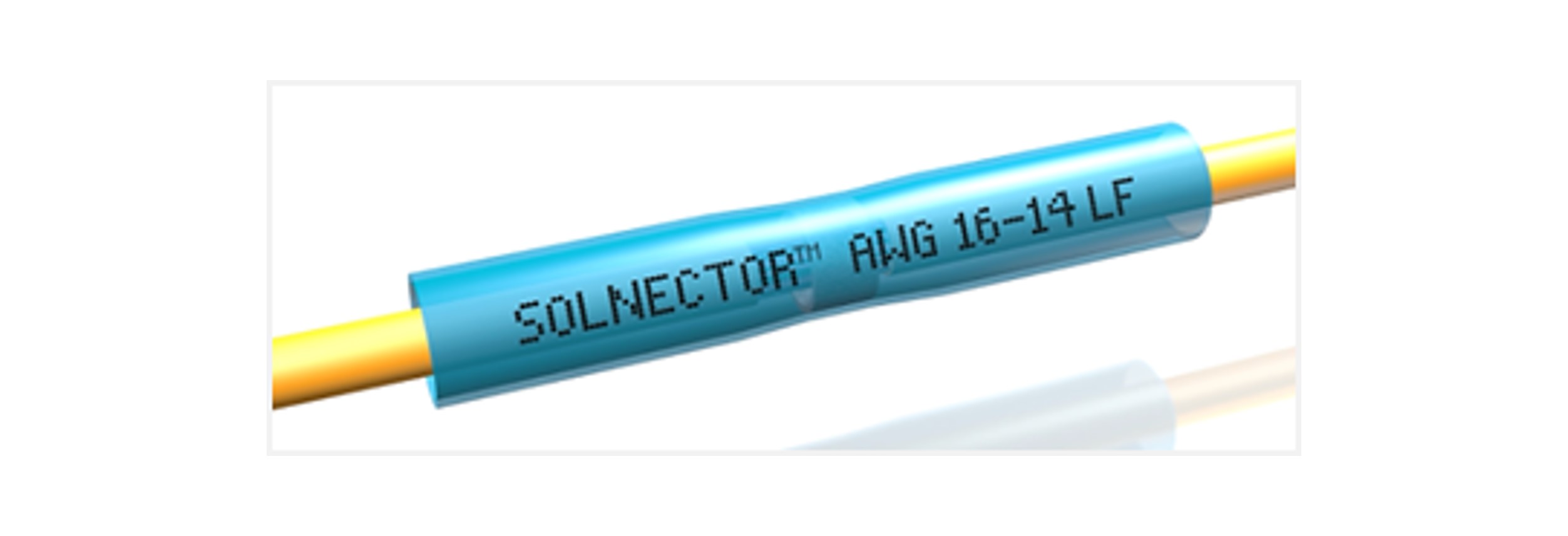

Solnector of ORIENS Korea Co., Ltd. is a connector for wire connection that is designed as all-in-one with bonded heat shrink tube and preform solder. Since the preform solder applied to the solnector is designed as a lead-free low-temperature solder having a low melting point of 138°C, it is possible to perform fast and reliable soldering work with hot air work, and the wire connected by soldering has excellent current flow and strong tensile strength. The bonded heat shrink tube of translucent polyolefin material has a shrinkage ratio of 3:1 and can be widely applied to various wires. When connecting the wires of the solnector, it is possible to visually check the soldering process inside the solnector and its work progress. In addition, the bond applied to the inner surface of the tube prevents corrosion of the wire connection area and blocks the inflow of moisture and contaminants. Wires connected using solnector can be connected more safely by providing soldering, insulation, and waterproofing.

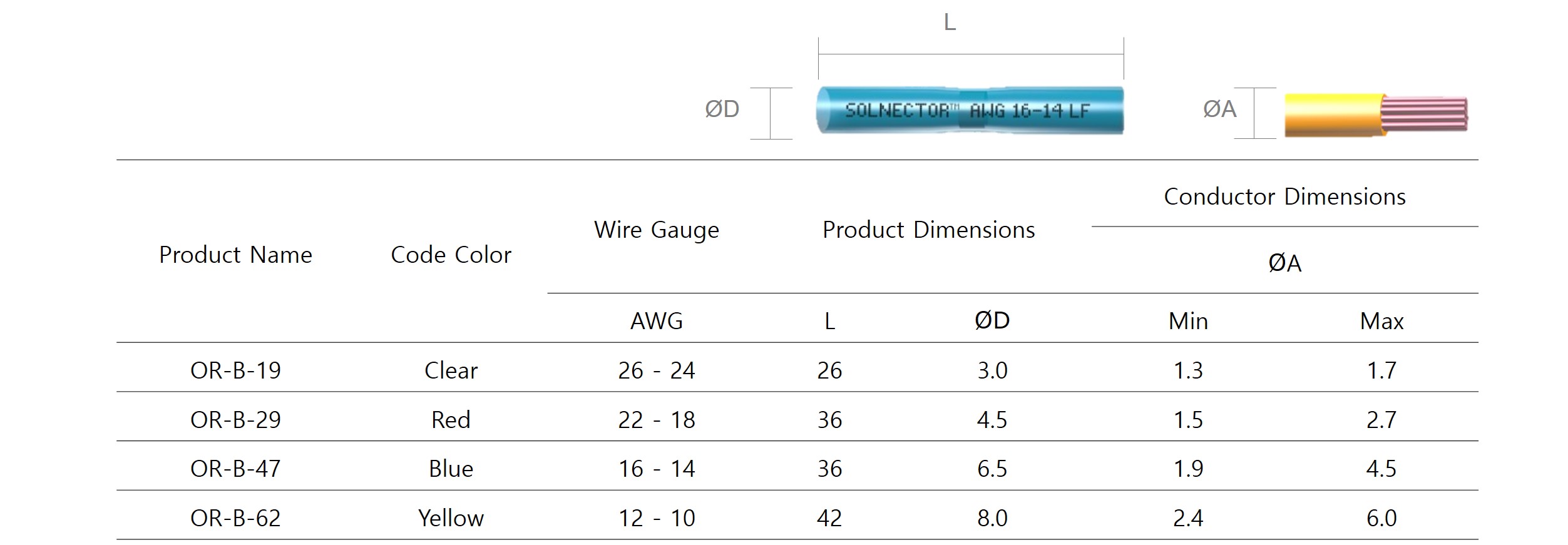

Specifications

• Temperrature : -40° to 105°C • Voltage : 600 Volts

• Temperrature : -40° to 105°C • Voltage : 600 Volts

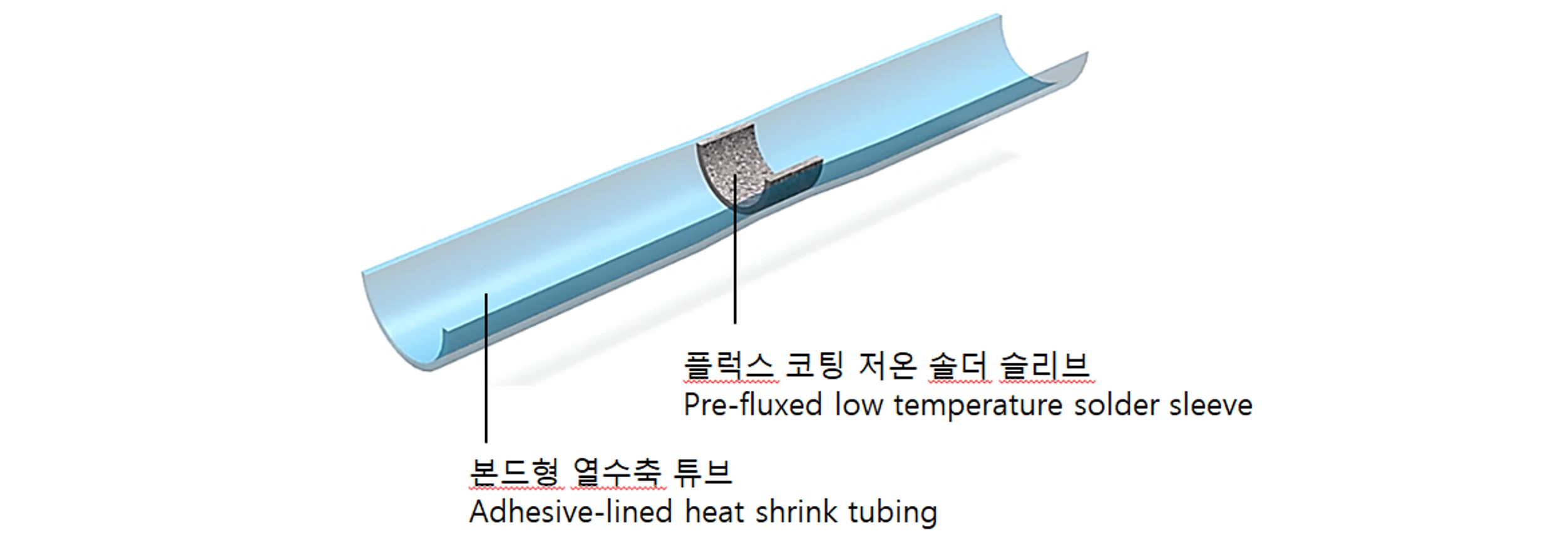

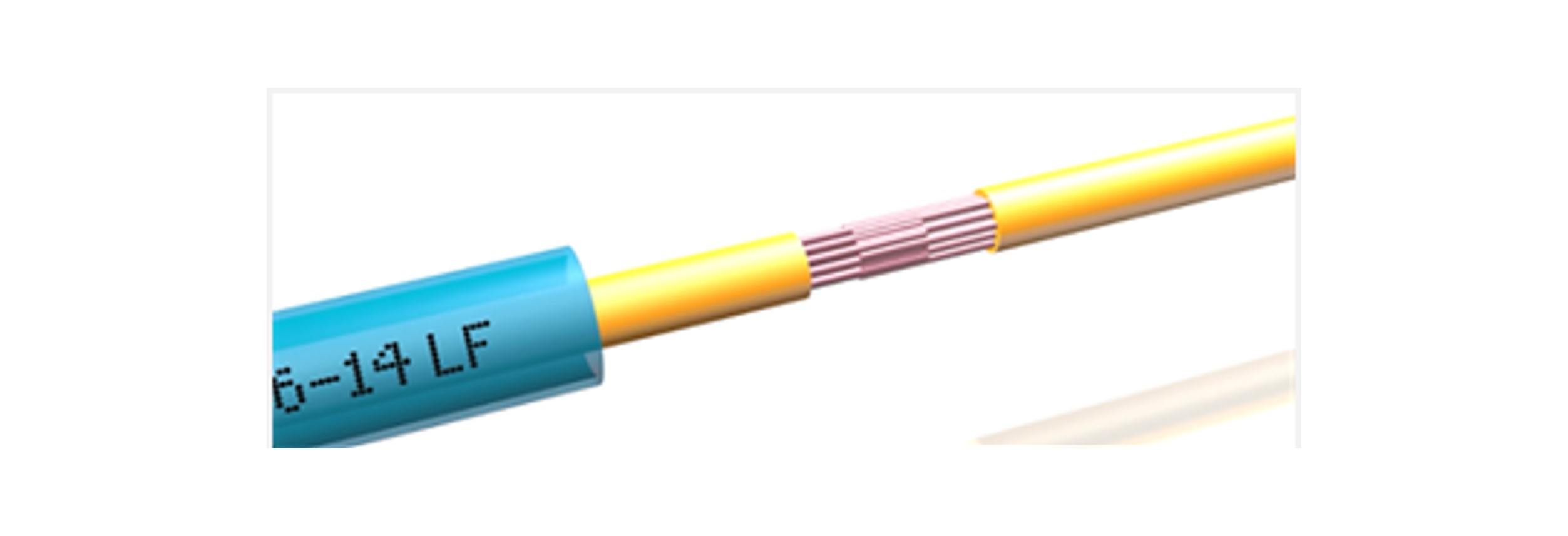

Product composition

Bonded heat shrink tube double pipe structure

(Outside: Polyolefin, Inside: Bond)

Flux-coated low-temperature solder sleeve

Flux-coated low-temperature solder sleeve

Installation

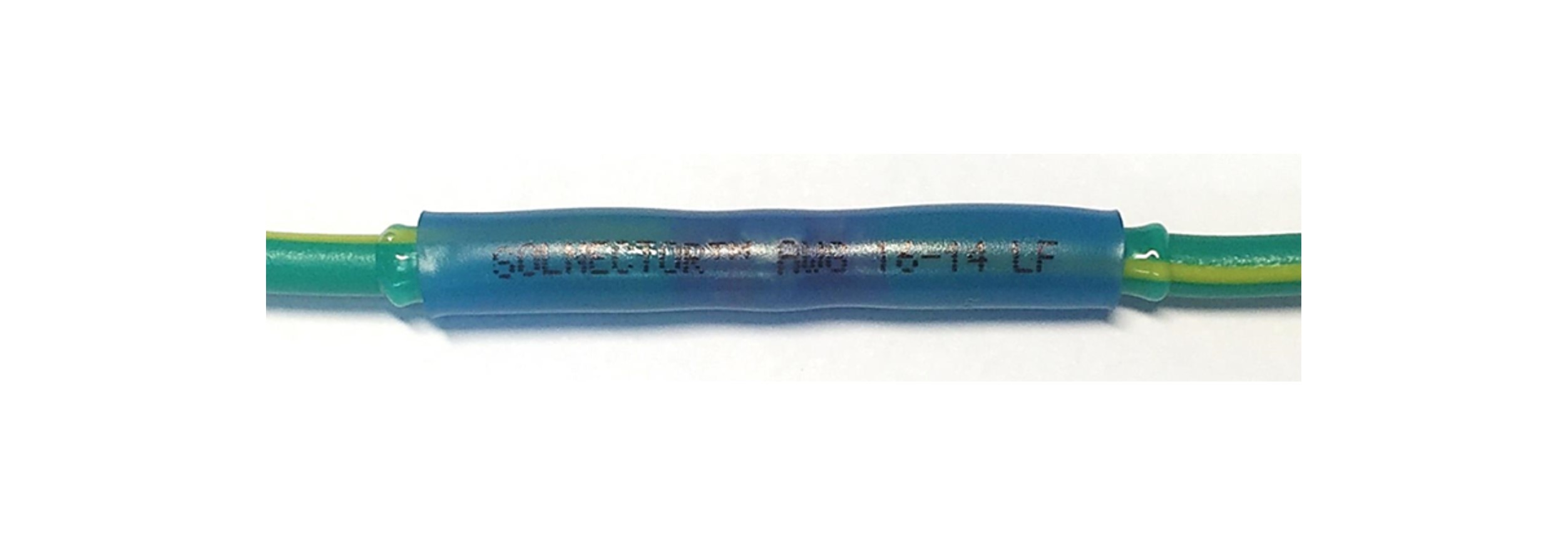

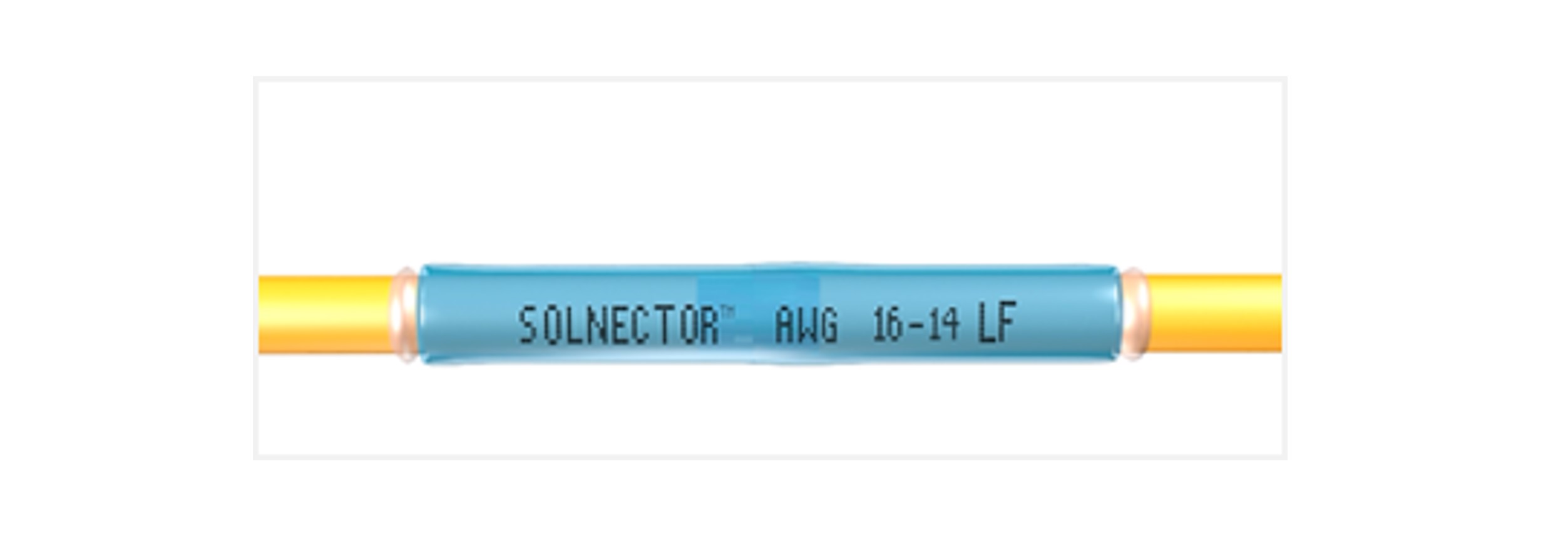

Insulation and sealing state of wires connected using Solnector

Soldering status of wires connected using Solnector

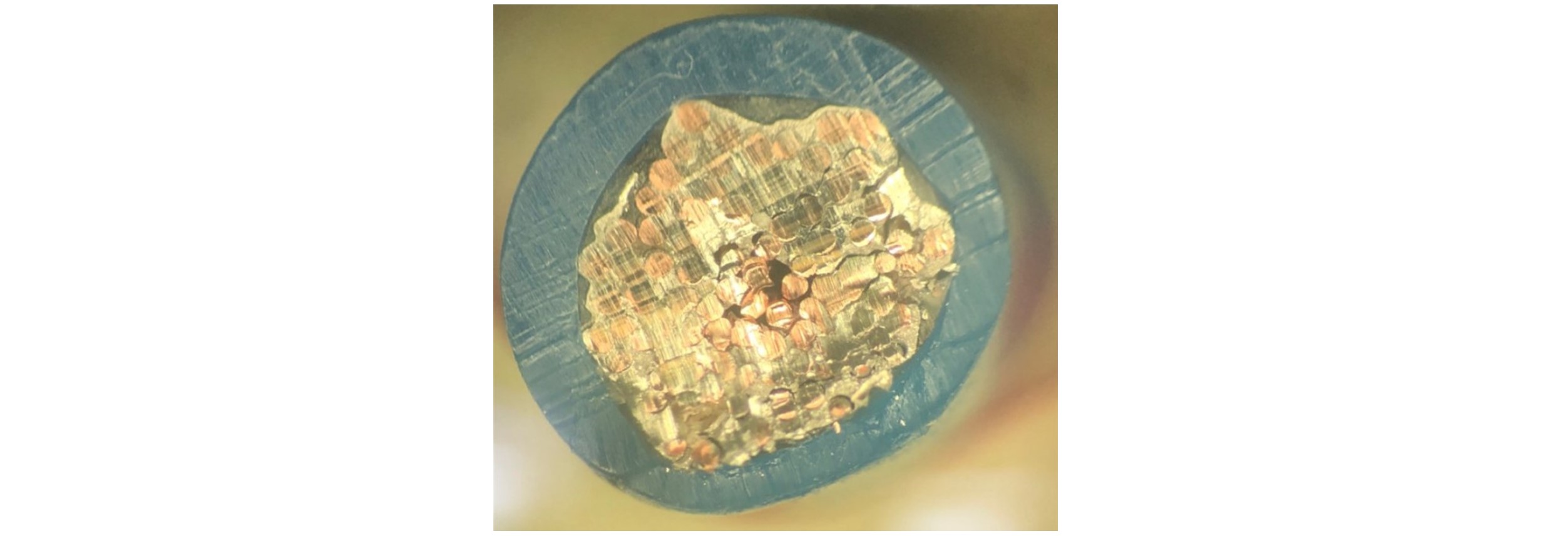

A cross-sectional photograph of the wire connection area connected using Solnector shows the state in which

A cross-sectional photograph of the wire connection area connected using Solnector shows the state in which the wires are connected by soldering,the bond is sealed around it, and the outside is insulated by the shrink tube

How to use

"When connecting wires using Solnector, cut off the power before use"

1. Select a Solnector that conforms to the wire specification and peel off the ends of the wires to be connected

(Peeling off section : 10-12mm)

2. Connect the strands of wires after pre-inserting the solnector into one wire

3. Place the Solnector in the center of the connected wire

3. Place the Solnector in the center of the connected wire

4. Place a heating fan equipped with a reflector in the center of the connected Solnector

4. Place a heating fan equipped with a reflector in the center of the connected Solnector(The temperature of the heating fan is 300 - 400 °C)

5. Blow hot air and apply heat evenly until the solder melts between the wires

5. Blow hot air and apply heat evenly until the solder melts between the wires

*You can check the soldering process through the transparent shrink tube*

6. After the wire connection is completed, it does not move until the connection part cools down sufficiently

6. After the wire connection is completed, it does not move until the connection part cools down sufficiently(Cooling time: around 10 seconds)

Used tools

When working with solnector, use a heating fan after connecting a reflector nozzle

10mm nozzle (Reflector)

Steinel Heating Gun